CEG CHEM Co., Ltd created in 2000. From its very beginning of establishment, we are dedicated in manufacturing pigment dispersions including paints, printing inks, liquid colorants and pigment paste. Located in the area where bounders with three provinces (Zhejiang, Anhui, Suzhou) called North District of Industrial Park in Yinxing of Jiangsu. It has very convenient transportation, only 160km far from Shanghai, Ningbo or Hangzhou port.

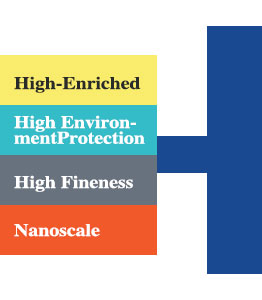

Our factory insists on upgrading and developing technologies, introducing advanced production process and equipment, applyinVg nano-tech to disperse and prepare pigment, So we further promote our products’ level and have realized high dispersion, high concentration and high fineness. We always follow EU top limited environmental-protection value and regard it as our adhering concept. Our products are widely used in cosmetics, textile coating, artificial and genuine leather, shoe materials, paper making, building coating, aqueous industrial coating, plastics, rubber,

profiles extrusion and myriad fields. We customJize multi-purpose pre-dispersed liquid colorant, pigment paste, color concentrates, color chips, color caky and application printing ink to match up their production. We are equipped with independent foreign trade department, exporting to more than 30 countries and areas including Southeast Asia, North America, South America, Europe.

|

|

|

|

“CEG CHEM” insist the sustainable development of the high-tech road, and insist people-oriented strategic concept, together with our friends and get rid of the stale and bring forth the fresh, continue to expand in emerging markets, transform conventional industries, in order to improve and meet updated technical index and economic value, in order to develop environmentally friendly products.

Develop and produce liuqid colorant, color chips, color sand, colora paste, color concentrate and special ink

/ Offer you the most suitable color technology solutions

| |

Pigment---It's a particle matter used for coloring, which is insoluble scattered in the medium, almost do not react with medium at the same time, and go through secondary processing, the paint processing usually is that using disperant and dispersing auxiliary to disperse it in advance, with high shear force, high impact of precision machinery, grinding, shearing the powder pigment with dispersion, auxiliary and give full play absorption effect of medium on the surface of powder, with the aid of space effect making the dispersion has a good stability, Change the particle surface polarity, increase pigment dielectric performance, improve the tinting strength and glossiness, preassigned medium and the easy dispersibility, Easy to measure, low dust or non-dust of pigment to improve the working environment and storage stability of the products.

|

|